|

HLMedicalŌĆÖs disposable acupuncture needles are sterilized medical device commissioned to professional sterilization company, and made using carefully selected, high-quality stainless materials for medical use and prepared by professional washing, dry system packed disinfecting environment prior to processing by a standardized large production system

The companyŌĆÖs quality management system is ISO13485 certified, and the products have FDA and CE qualifications.

|

|

All useable acupuncture needles for medical use have a common standard for biohazard safety.

Following the ISO 10993 standard, we use stainless SUS 304 nonmetallic wire for traditional acupuncture needles.

|

|

|

| To make the needle length acurate, we adopt the automatic cutting machine and apply weave finishing. |

|

|

After the spring is evenly produced by automatic equipment, its surface is washed and polished by an automatic barrel process. |

|

|

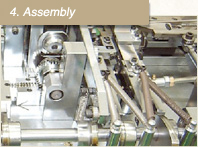

For the best performance of stiffness, resistance, and soft touch, the needles and springs are put together by an automatic assembly process. |

|

|

| To minimize the pain inserting needles into the skin, the edge and the tip of the needles are grinded and polished by specialized techniques of the company. |

|

|

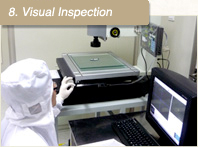

After processing the needle tip, a lab inspector exams the length of the needles and the smoothness of the needle surface. Only the passing needles are sent to the washing room.

|

|

|

We use 99% Pure Water and the system according to GMP standards and use 5 steps of washing by using an ultra washing equipment to completely eliminate the remains on the surface of the needles. |

|

|

After washing, drying, and selective examination, entire needles are sent to alchol disinfection processor to achieve the optimum cleanliness.

|

|

|

|

Here, we inspect the needle's elasticity, tension, flexibility for the final process. |

|

|

| After the washing, entire needles are checked, including the body and tips' cleanliness by a two dimensional exam machine. |

|

|

| To minimize the pain during treatment, we apply the silicon coating, which passes the biohazard safety, on entire products before packaging. |

|

|

To seal in disinfected environment, individual package equipment is strictly administered.

Each production route is strictly administered to safely reach to customers. |

|

|

| The packaged and finished acupuncture needles undergo eo gas gamma ray stereilization at a gamma ray facility enforcement.

|

|

|

All the packaged productŌĆÖs route number and useable time slot is recorded on the outside. Therefore, all produced productŌĆÖs history which are the productŌĆÖs inspection, sterilization, and qualifications can be confirmed.

|

|